If you are manufacturing products and selling them to the market, you should understand about barcodes and UPCs for product labels. In fact, understanding UPCs (Universal Product Codes) and barcodes is crucial. Not only that this is the right way for labeling your products. More than that, it will help you in managing inventory and tracking sales. In this guide, we will cover everything you need to know about UPCs and barcodes on product labels.

Know More about UPCs and Barcodes

What is a UPC?

A Universal Product Code (UPC) is a unique code used to identify products in stores. Accordingly, each product has its own UPC to distinguish it from others. Custom packaging for products often includes these UPC codes to ensure seamless tracking and inventory management.

So, what is a UPC barcode?

A UPC barcode is the visual form of the UPC code. Typically, it consists of black and white bars that can be scanned to read the product’s unique code.

The UPC code is a 12-digit number that identifies a product. In addition, it includes information about the manufacturer and the product itself. Moreover, the 12-digit number is assigned to each product. Customized boxes often feature UPC barcodes for efficient tracking.

So, speaking of what does UPC mean, this code is a unique identifier for a product, used for tracking inventory, sales, and more.

Why Should You Use Barcode Labels and Display?

A barcode scan reads the barcode and converts it into data that can be displayed on a label or stored in a database. This means that having a barcode on a label is essential for quickly identifying and tracking products.

A typical barcode label might include the product’s UPC barcode, a description, price, and other relevant information. Custom packaging boxes with barcodes are particularly useful for managing and selling products efficiently.

The main purpose of labels with barcodes is to help in tracking, managing, and selling products efficiently. This is why they often include additional information like product name and price.

What Are the Specific Types of Barcodes?

To get a better understanding, let’s have a look at some specific types of barcodes

- Box UPC Code

A box UPC code is printed on the packaging box of a product. This code is useful for tracking inventory and logistics and is often featured in custom packaging with logo.

- Barcode for Products

Barcodes on products will help to identify and track them throughout the supply chain. For this reason, you will find each product variation having a unique barcode.

- Barcode for Cosmetic Products

Yes, cosmetic products also have barcodes to help manage inventory. Also, the barcode helps to ensure accurate scanning at the point of sale.

A cosmetic barcode is specifically designed for cosmetic products to ensure they are uniquely identifiable.

- UPC Barcode

A UPC barcode is the visual representation of the UPC code, used for scanning and tracking products.

- Barcode Item

A barcode item is any product with a barcode on its packaging or label.

- UPC Barcode Finder

A UPC barcode finder is a tool or service to look up product information based on the UPC barcode. As the name suggests, this tool helps retailers and customers find product details quickly.

Miscellaneous Barcodes for Products

Since there are various types of products in the market, you will also come across miscellaneous barcodes for products.

What are they?

- Barcode Giant

A barcode giant refers to a very large barcode used on oversized products. The main purpose of this barcode is to ensure easy scanning.

- Double Barcode

A double barcode occurs when a product has two barcodes, which can cause scanning errors. Thus, it is important to use only one barcode per product.

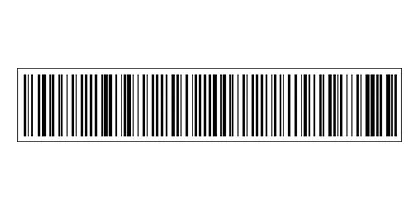

- Barcode Strip

A barcode strip is a long, narrow barcode used on products with limited space for labels.

- Sample Barcode

A sample barcode is used on product samples for tracking and inventory, just like regular products.

- Tiny Small Barcode

You can find these tiny small barcodes on products with limited label space. This type of barcode is designed to be small yet scannable.

- Small Barcode Labels

Small barcode labels are perfect for smaller products where space is limited. The barcode typically includes all necessary information in a compact format.

Understanding and Reading Barcodes

Now here’s a big question you might have; How to Read Barcode Numbers?

Reading barcode numbers requires you to have a good understanding of their structure. Of course, scanners and software decode this information. However, understanding the structure helps in manual interpretation.

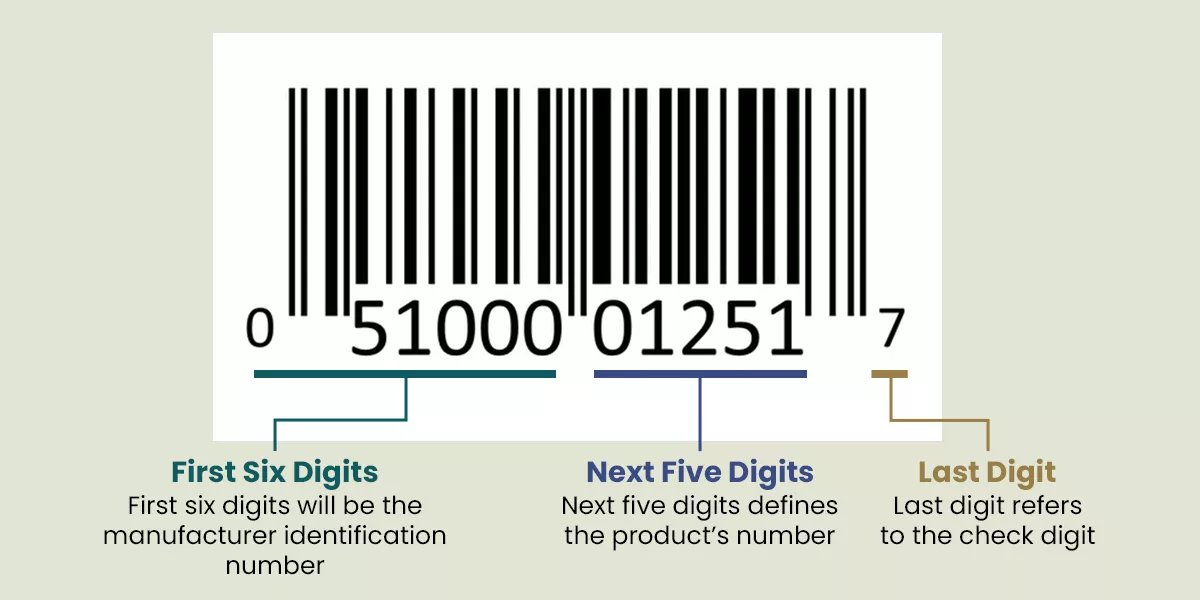

So, there are different parts of that 12-digit code. Accordingly, each part comes with its different roles.

- First six digits will be the manufacturer identification number

- Next five digits defines the product’s number

- Last digit refers to the check digit

What are QR Codes?

QR codes (Quick Response codes) are two-dimensional barcodes that can store a significant amount of information. The great thing is that they can be scanned using smartphones or QR code readers. Unlike traditional barcodes, which are read horizontally, QR codes can be read both horizontally and vertically.

Here are some Key Features of QR Codes:

Structure

A QR code consists of black squares arranged on a white background in a square grid. The pattern includes unique markers that help scanners recognize and read the code quickly.

Data Capacity

QR codes can store various types of data, including URLs, text, email addresses, phone numbers, and even small amounts of binary data.

Flexibility

Yes, QR codes are flexible in numerous applications, such as:

- Marketing: Directing customers to websites, social media profiles, or online stores

- Payments: Facilitating quick and secure mobile payments

- Product Information: Providing detailed product information or instructions

- Event Management: E-tickets and event registration

- Logistics: Tracking shipments and inventory.

How Big Does a QR Code Need to Be?

The size of a QR code depends on the amount of data and the scanning distance. The minimum print size for a QR code is typically around 1 x 1 cm. However, it should be larger if it contains more data or if scanned from a greater distance.

What’s the Difference Between Barcodes and QR Codes?

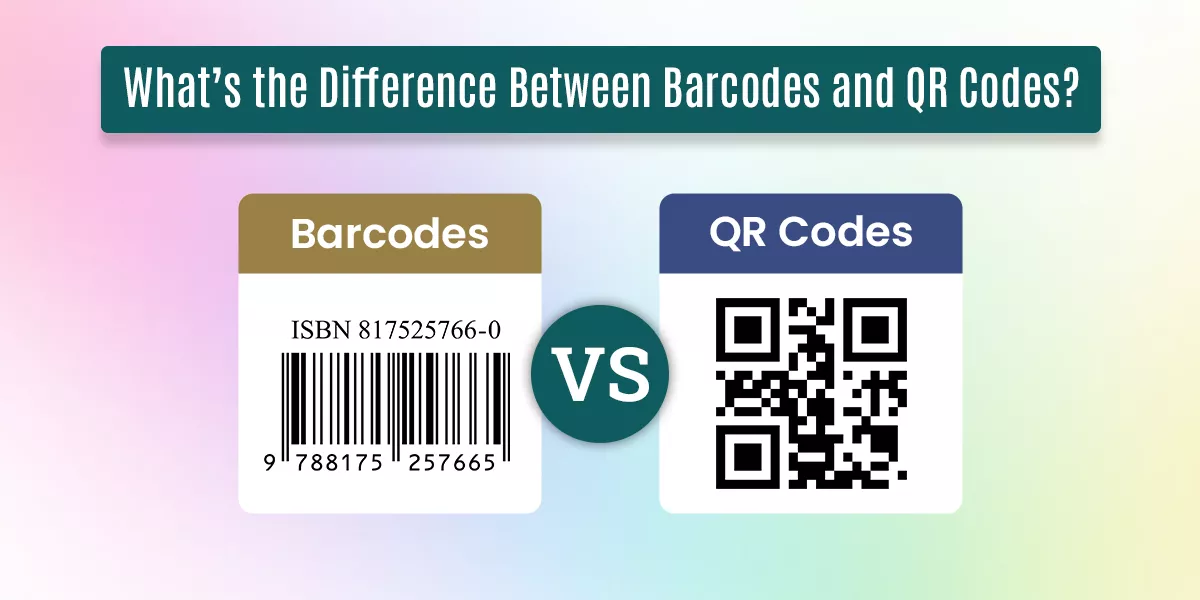

Barcodes and QR codes are both used to store. Also, they both are useful to transmit information quickly and efficiently. However, they have distinct differences in terms of structure, capacity, usage, and functionality.

- Barcode

Barcodes are one-dimensional (1D) and consist of a series of parallel black and white lines of varying widths. You need to read barcodes horizontally, from left to right.

- QR Code

QR codes are two-dimensional (2D) and consist of black squares arranged on a white background in a square grid. You can read QR codes both horizontally and vertically.

How to Get a Barcode for a Product?

If you wish to get a barcode for a product, you need to register with a barcode authority like GS1 (supply chain standards designed to facilitate efficient business communication between trading partners). They provide unique barcode numbers for your products.

How to Make Sure Your Label’s Barcode and UPC Work?

Ensuring your label’s barcode and UPC work correctly is essential for product tracking, inventory management, and sales processing.

Here are some requirements you should follow!

Appearance

- Apply the right colors

Make sure you apply black bars on a white background on your barcode. This will ensure scanners can easily read the barcode. Custom packaging for product providers should maintain high print standards.

- Focus on the print quality

Your barcode must be printed clearly without any smudges or fading.

- Material

Use high-quality label materials that will not distort the barcode.

The Barcode Size

The typical UPC barcode size is 1.469 inches wide by 1.02 inches high. This size ensures easy scanning. Meanwhile, the smallest acceptable size for a UPC barcode is 80% of the standard size (1.175 inches wide by 0.816 inches high).

Readability

Make sure that your barcode is big enough to be easily read by scanners. However, it should not be too large because it takes up too much label space.

Proper Barcode Placement

Place the barcode on a flat part of the product packaging. Remember to avoid curved surfaces or edges that might distort the barcode. Plus, make sure that the barcode is in a visible area where it will not be covered or damaged.

In addition, you must also place the barcode consistently on all products. For the common spots, you can place it at the bottom right corner or the center of the back of the package.

The Right Format to Print Your Barcode

Provide your barcode to the printer in a high-resolution format (at least 300 dpi). This way, you will get clear and accurate printing. You must also use vector formats like EPS or PDF for the best quality.

Environmental Considerations

Ensure the label and barcode on your product can withstand factors like moisture, heat, and abrasion. For this, you must use strong adhesive labels that will not peel off easily.

Compliance

Always follow industry standards and guidelines for barcode creation and placement, including adhering to GS1 standards for UPC codes. Most importantly, make sure that your barcodes comply with any regulatory requirements specific to your industry or region.

Wrapping Up

Indeed, by understanding UPCs and barcodes, you can ensure efficient product labeling. Moreover, you can get accurate inventory management and seamless sales processing. Whether dealing with small cosmetic products or large products, the principles of barcode use remain essential for modern retail operations.

To get assistance in placing your barcodes for product labels, you can contact Silver Edge Packaging today!