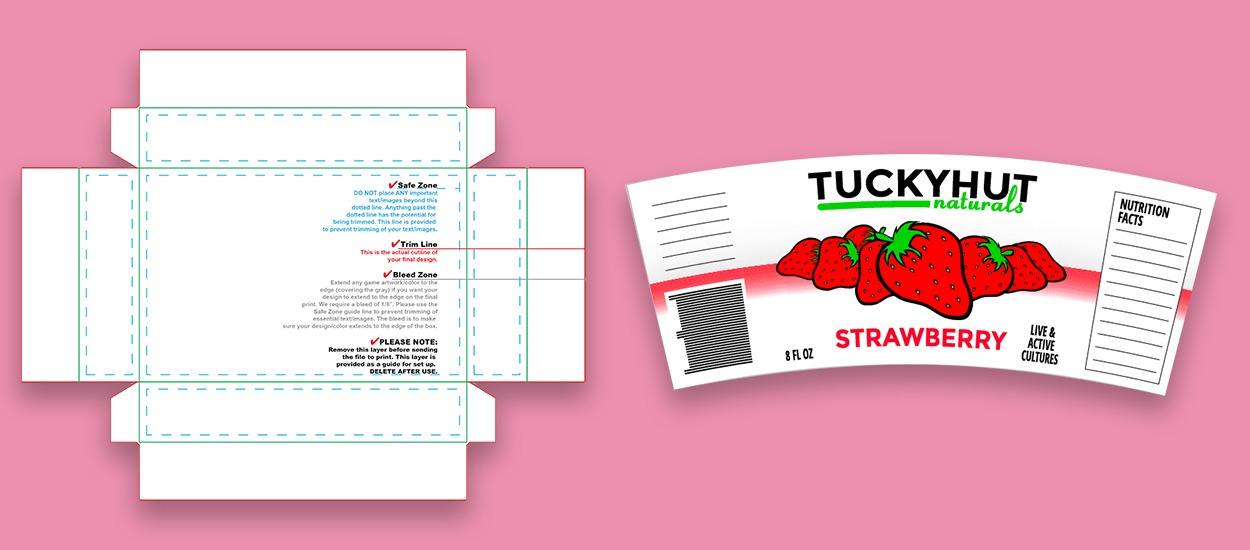

A dieline is a package template that ensures a printed product will have the right layout. It is a diagram showing a package’s flattened cut lines and folds. Additionally, you can use them for other forms of packaging, including bags, boxes, and envelopes.

These dielines function as frameworks and graphic representations of the package you intend to create. These dielines are created by packaging designers based on the size, shape, and printing requirements for boxes of various sizes and shapes.

As a result, you must use manual or digital design tools to measure and draw the design of the boxes. The lines in these templates denote the dimensions and gaps of the packaging’s various sides.

Difference Among Die, Dieline, and Dieline Labels

Dielines are crucial package design components and are created per a detailed set of rules and industry standards. A dieline is the artwork or pattern that the die uses as a direction when creating cuts, scores, and indentations on printed materials. A die is a tool that trims, scores, or makes an impression on printed materials.

Thus, a die is a piece of equipment used to score, cut, or indent printed materials. On the other hand, a dieline is the design or contour that the die follows when creating cuts, scores, and indentations. Dielines, created according to a particular set of guidelines and industry norms, is essential to the package design process.

Dieline is generally used to create a box’s template, but it is also essential for labeling. Additionally, dielines specify how printing for labeling will be done. This dieline template, to put it simply, also instructs the printer to print exclusively within the designated areas and points.

For labels, symmetry and a suitable layout of your artwork are crucial. Dielines, therefore, serve as stand-ins to establish a suitable arrangement of templates that will be die-cut as part of the finishing process.

Designer of Dieline for Packaging

A dieline, also known as a die line or cutting line, is a vector artwork file that indicates where the packaging should be cut, folded, or perforated during the manufacturing process. It is an essential tool in the packaging design process, as it helps ensure that the finished product will be accurate and functional.

The dieline is typically created using computer-aided design (CAD) software and includes precise measurements and specifications for the size and shape of the packaging, as well as any features such as flaps, tabs, and openings. It also includes any necessary registration marks, which help align the printing and cutting processes during manufacturing.

A packaging graphic designer creates the dieline digital design using any graphic design software as the first step in this process. The design team also calculates and estimates each component and feature of a dieline template.

Though you can try to design your dieline, but graphical expertise is important in this regard. Dielines are often created by graphic designers, die cutters, and printers to produce a number of various packaging materials, such as basic to intricate boxes, pocket folders, envelopes, food and beverage packaging, brochures, displays, and anything you can imagine in 3D.

Significance of Dieline in Packaging

The dieline is used to create a die, which is a metal tool used to cut and fold the packaging material. The die is typically made of hardened steel and is custom-made for each packaging design. The die is used in a die-cutting machine to cut and shape the packaging material according to the specifications in the dieline.

In addition to its technical role in the manufacturing process, the dieline also serves as a visual representation of the packaging design and helps designers and clients visualize the finished product. You can also use it to communicate the design concept and make any necessary adjustments before the packaging goes into production.

Overall, the dieline is a crucial element of the packaging design process and plays a vital role in ensuring that the finished product is functional and accurate.

Create a Dieline for the Packaging, Follow These Steps

Start by sketching out your packaging design on paper or using a digital drawing tool. Consider the size and shape of the packaging, as well as any features such as flaps, tabs, and openings.

Use computer-aided design (CAD) software to create a digital version of your packaging design. There are several software options available, such as Adobe Illustrator, CorelDRAW, and AutoCAD.

Add precise measurements and specifications to your design, including the size and shape of the packaging, as well as any features and openings. Be sure to include any necessary registration marks to help align the printing and cutting processes during manufacturing. Then, save your design as a vector file, such as a .ai or .eps file.

However, it is equally important to review your dieline carefully to ensure that it is accurate and complete. It is good if a professional packaging designer or engineer checks to ensure that it is functional and will work correctly during the manufacturing process.

Use your dieline to create a die, which is a metal tool to cut and fold the packaging material. The die typically is of hardened steel and is custom-made for each packaging design. It is useful for the die-cutting machines to cut and shape the packaging material according to the specifications in the dieline.

Wrapping Up

We have explained the process of designing a dieline; by following the exact steps, you can create a dieline that will help ensure that your packaging design is accurate and functional. However, it is crucial to note that doing such a task is not the job of everyone.

Our professional designers strategize all designing duties at Silver Edge Packaging efficiently. Before transferring the design to a production house, we take care of each design aspect, including dieline. Then, we double-check these designs and get approval before sending in the production house to ensure that these designs are accurate. Compliance officers and environmental engineers ensure quality assurance from design to final production.

We make our service the most affordable and safe for you to avail. Even more, all these services are free for our beloved customers and clients. You get suitable packaging for your brand, free design support, free one-color printing, and consultation.