It has become important to measure the dimensions of a box in the era of e-commerce. The measurements of the boxes have become important in consideration of product protection. This means you need to pay close attention to measuring a box accurately to package the products perfectly. Therefore, the dimensions of packaging influence the necessary material with the cost of production and shipment.

Box Measurement Process

In this blog, we are going to discuss essential steps for measuring the dimensions of a box perfectly to calculate the total volume to ensure the ultimate protection of products.

How To Find The Volume With Accurate Measurements

You need to consider the length, width, and height to measure the volume of a box. This means that the process starts with taking accurate measurements of the longest, shortest, and vertical sides of the box. You need to multiply the height, width, and length to find out the total volume of the box. It is crucial to use the same unit, such as an inch, to measure all three dimensions of boxes.

When you have to measure the dimensions of a non-rectangular box, you need to consider more specific calculations by the geometry of the boxes. Moreover, it is a good approach to consider irregular shapes like the different geometric figures such as cubes and spheres. After the measurement is completed, it becomes easy for you to calculate the volume of custom product packaging.

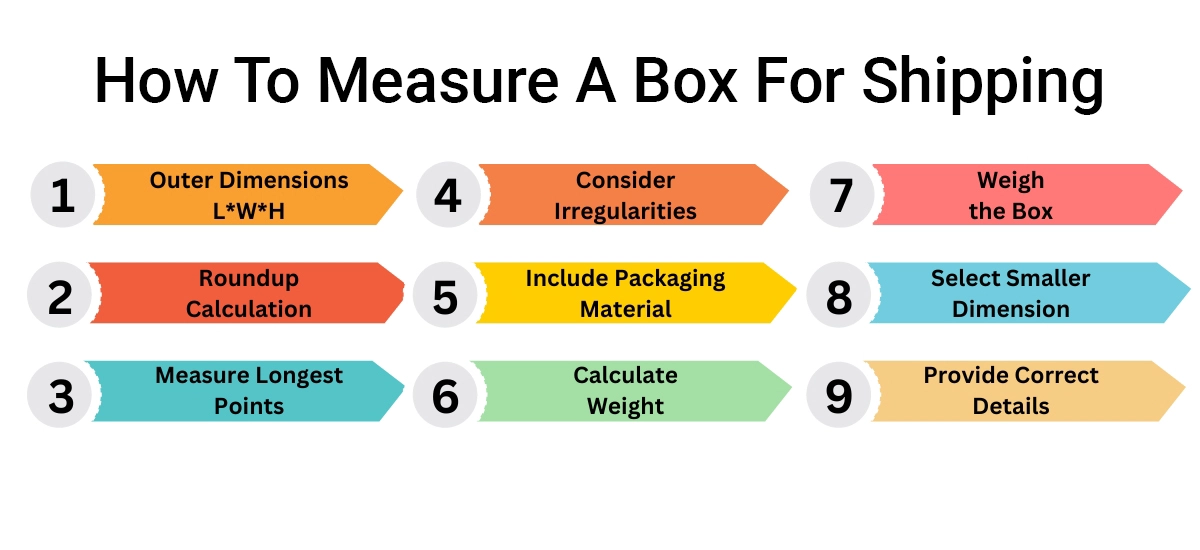

How To Measure A Box For Shipping

The dimensions of a box are usually listed in the sequence of length (L), width (W), and (H). It is necessary to take the correct measurements of dimensions to know the exact shipping costs to avoid problems during the shipment process.

- Outer Dimensions: Consider the outermost length, width, and height.

- Roundup Calculation: It is good to consider the roundup consideration. If the exact length is 9.4 inches, you must round it up to 10 inches.

- Measure Longest Points: You need to consider the longest points, such as handles, for measurement.

- Consider Irregularities: If a box has protruding parts, you must consider them with the maximum dimensions for accurate measurement.

- Include Packaging Material: When you ship a box without the larger container, you must take the measurements of the packaging material, such as padding or wrap.

- Calculate Weight: Different shipping carriers consider the dimensional weight to calculate the shipment costs. You can multiply the length, width, and height and divide them by the carrier dimensional factor, such as 139 or 166 for local shipment in the USA.

- Weigh the Box: The next step is weighing the box with the package to determine the total shipping cost.

- Select Smaller Dimension: When the box is not in the rectangular or cubic form, you must go with the smallest dimension to measure the box.

- Provide Correct Details: When you are using the shipment center or online service for shipping, you need to provide the correct information on weight and dimensions for proper billing with on-time delivery.

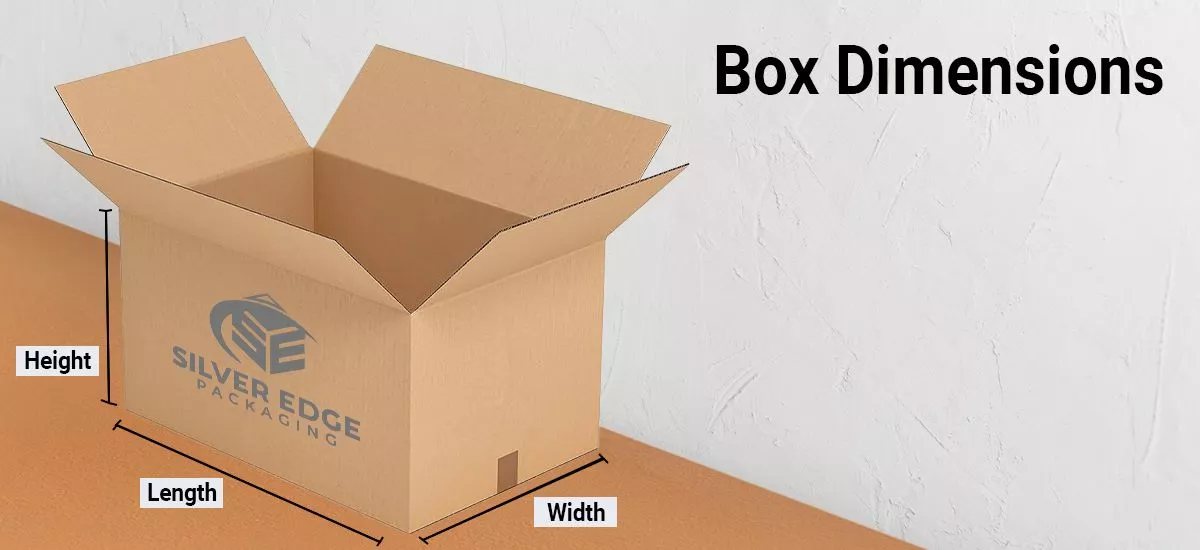

Box Dimensions and Sizes

The sizes and dimensions of the boxes have a crucial role in calculating the volume and weighing the boxes for shipment in a flexible way.

Box Dimensions

There are three popular types of dimensions for measuring an ox easily. These dimensions include length, width, and height.

- Length (L): The longest side of a box.

- Width (W): The shortest side of a box.

- Height (H): The vertical side of a box.

When you see dimensions 9 x 6 x 4, it means the length is 9 inches, the width is 6 inches, and the height is 4 inches. The calculation of dimensions is important for packaging, storing, and shipping different products. The most common units for measuring the dimensions of the box are centimeters and inches.

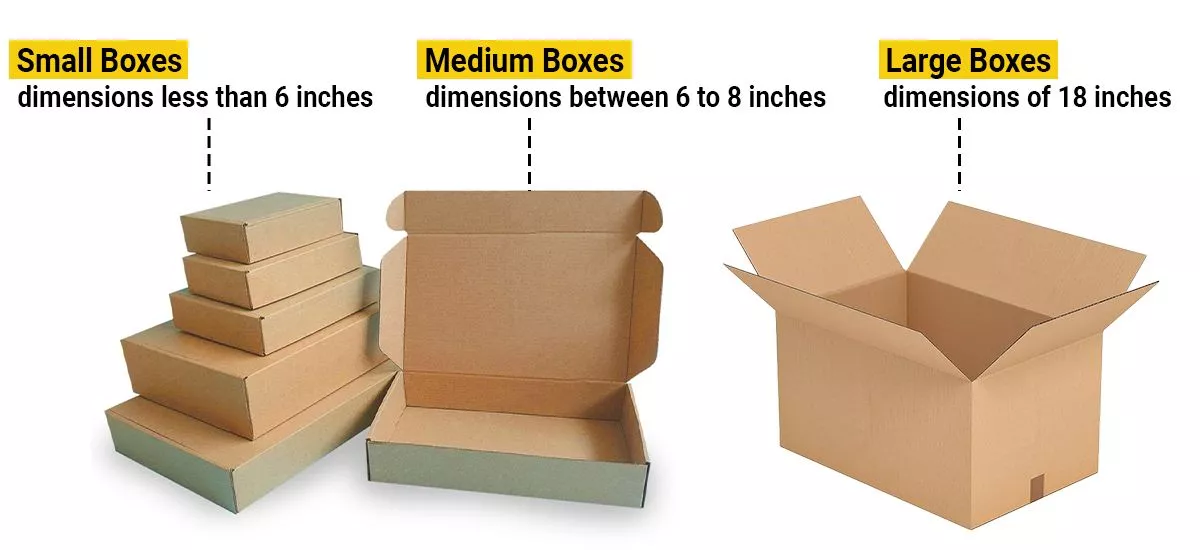

Box Sizes

There are three types of boxes according to the size:

- Small Boxes: Small boxes are usually available in dimensions less than 6 inches. These are the perfect boxes for different products, such as cosmetics, small electronics, and jewelry.

- Medium Boxes: The medium boxes commonly have dimensions between 6 to 8 inches. These boxes offer excellent packaging solutions for kitchenware, books, and clothing.

- Large Boxes: The large boxes often have dimensions of 18 inches. These are the ultimate choice for packaging toys, large electronics, and different household items.

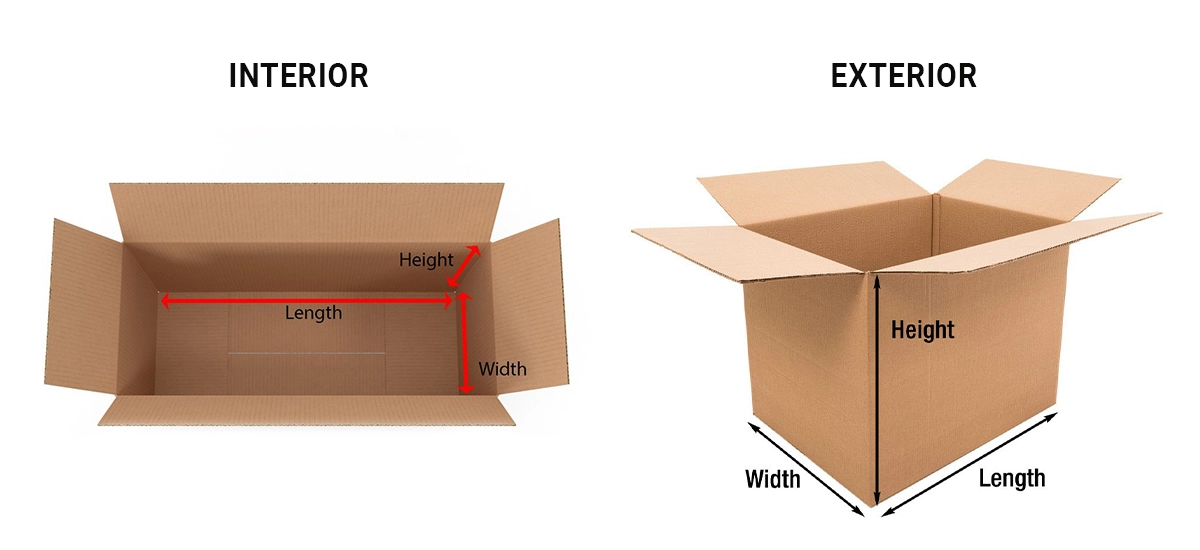

Always Measure Both Interior And Exterior Dimensions Of The Box

Most people usually make the common mistake of considering the outside dimensions for measurement. This approach can not help you to learn about the thickness of a packaging box. When you are using a corrugated cardboard box, the double-walled structure can cause extra bulk. Therefore, you need to consider the interior measurement to ensure that your products are perfectly placed in the boxes.

When you are just focusing on the measurement of the outermost dimensions, you are increasing the chances of squeezing for your products, resulting in the customer’s dissatisfaction. Therefore, you need to think professionally and consider the interior measurements alongside the exterior measurements to ensure the necessary safety of your products.

Importance of Measurement For Box Dimensions

Boxes offer the ultimate safety to products and also boost the lifespan. They also are great sources of marketing your business to potential customers who are looking to buy your products. Your products are not going to attract consumers with ordinary packaging, which means you need to go the extra mile to design the packaging.

It is always a good approach to do your homework to compete with the competitors in your specific business category. Boxes always play the role of the front liner to spread your brand awareness and generate more sales for your business. These boxes safeguard your products from damage during the storage and transportation process.

It is a fact that your products go through different hands before reaching the ideal destination. Therefore, you need to use the best packaging solutions, such as custom drawer boxes, to ensure the original state of your products and satisfy customers. Therefore, it is crucial to consider the dimensions of storing and shipping the products.

Determination Of Box Space

The measurement allows you to determine the available space easily. You need to consider the space for storage and shipment. Therefore, it is crucial to know how much space a box and vehicle can take in the warehouse.

Calculation Of Shipment Cost

Weight and size are the factors most influential in calculating the cost of a shipment. You need to have the proper knowledge of the dimensions of the box to calculate the total shipment cost correctly.

Seamless Placement On Shelves

When you are looking to display your products on the shelves of a retail store, you need to consider the perfect dimensions to ensure compatibility with the shelves. It is important to consider that an extra-large box can not fit on the retail shelves.

Conclusion

This step-by-step guide is a helpful resource for you to measure the dimensions of a box to decide the total shipping cost with the available space. Moreover, you can get custom packaging for your business from Silver Edge Packaging Solutions to present your products and satisfy customers.