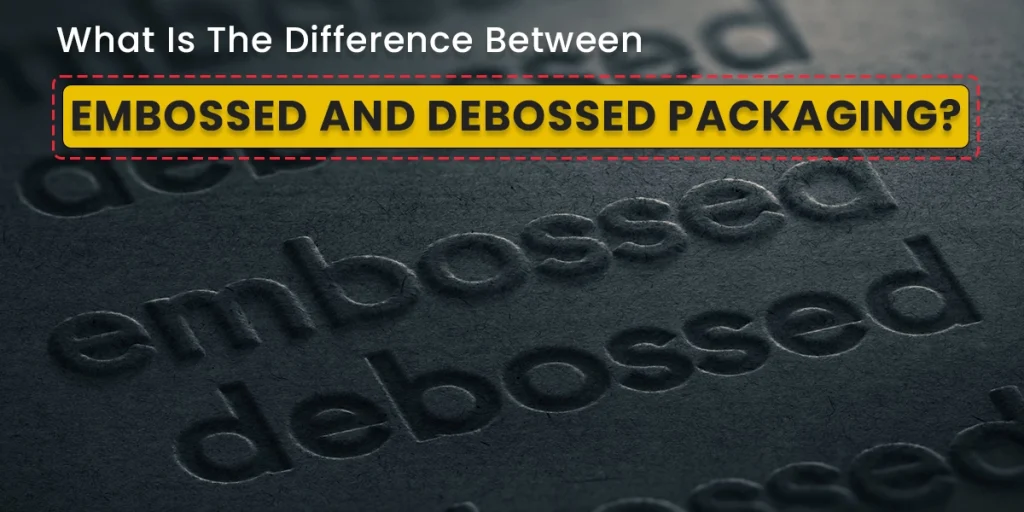

Embossing and debossing are two famous printing methods in the custom packaging industry. It is a fact that printing techniques ensure a prominent difference in the perception of different products. Debossing and embossing add a significant touch of texture and sophistication to the packaging. These packaging techniques offer unique effects to ensure distinctive purposes. However, what is the difference between debossed and embossed packaging?

What is difference between embossed and debossed?

When you are looking for different printing techniques to make your packaging more adorable and attract potential customers, it is necessary to know the different between embossed and debossed. Therefore, we will explore the main difference between these packaging printing techniques.

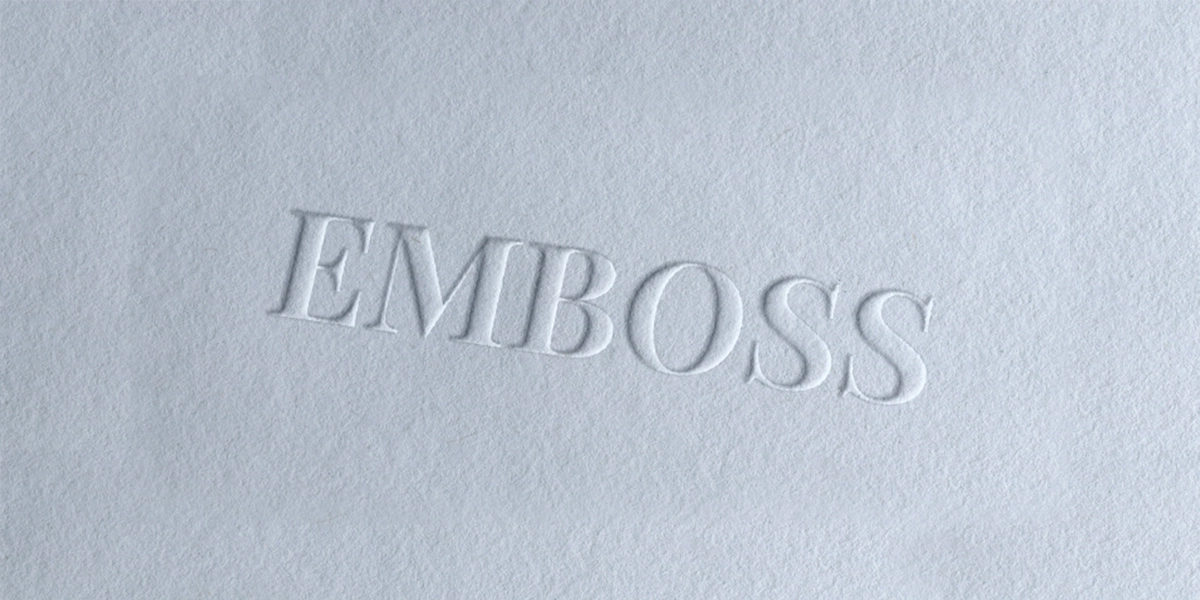

What Is Embossed Packaging?

What does embossed mean? It is a technique to raise the text or design above the surface of the packaging. You need to press the material between two molds, such as the female die for the recessed design and the male die for the raised design. This technique makes the protruded design offer a 3-dimensional effect to captivate the customers’ attention.

It is an ideal printing technique for the packaging of premium and luxury items to convey top-quality craftsmanship. Foil stamping, heat embossing, and die-cutting are ideal methods to create embossed packaging for your brand. Therefore, you can choose an ideal method to emboss the graphics to promote the sophistication and elegance of products.

Advantages Of Embossing

- Raised design provides the tactile element to engage customers and improve their interaction with the products.

- Embossing ensures a premium and luxurious look for the upscaling of products.

- The shadow and light on the raised texture and graphics create a fabulous visual effect to make your products packaged in custom embossed boxes stand out in the competitive market.

Disadvantages Of Embossing

- Expensive printing approach for packaging

Uses Of Embossed Packaging

- Raise brand logos to create a unique brand identity and unforgettable impression.

- Highlight the product name to make it noticeable to potential customers.

- Add the patterns and details to improve the overall design of the packaging.

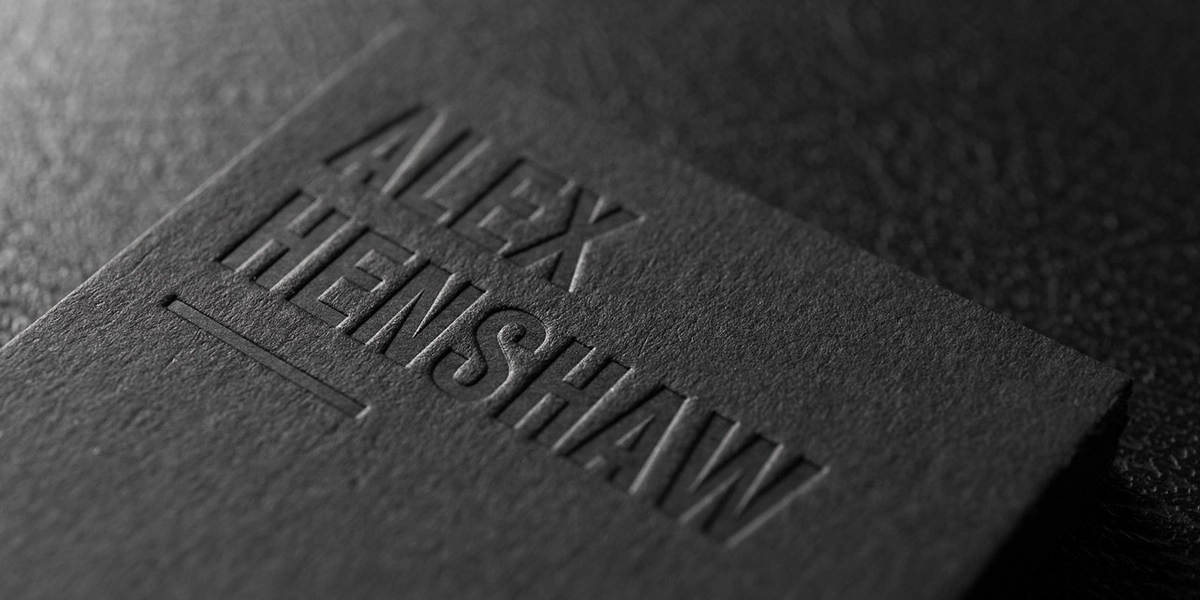

What Is Debossing?

What does debossed mean? It is a technique to press the text and design into the packaging surface to ensure a recessed effect. Female and male die methods are used for debossing to press the design inward. Therefore, design and text are recessed rather than raised in debossing vs embossing.

This printing technique is easily applicable to different materials, such as cardboard and paper. You can easily ensure a 3-dimensional texture on the surface of the packaging. A steel die is perfect for pressing into the surface to leave an excellent recessed impression. Therefore, it offers a tactile experience to the customers.

Advantages Of Debossing

- Enhanced durability because the recessed design is less impacted by tear and wear due to excellent material usage.

- Subtle elegance because debossing offers the refined appearance to align with products and promote sophistication effectively.

- Unique texture offers a distinctive tactile experience for numerous products.

Disadvantages Of Debossing

- A high level of craftsmanship is required.

Uses Of Debossed Packaging

- Background patterns allow you to add texture without overshadowing the primary elements of design.

- Recess logos and text help you to build a subtle and unique branding element.

- Highlight details on certain design parts in a discreet approach.

How To Choose Between Debossing and Embossing?

When it has become difficult for you to select between debossing and embossing packaging, you need to consider the following factors.

Brand Identity

Embossing is a perfect choice for brands searching to create a bold statement and emanate luxury. Debossing is an ideal choice for businesses that prefer elegance and subtlety.

Product Type

It is fair to say that premium cosmetic brands can easily benefit from an embossed packaging box. However, debossed packaging is ideal for the wine label.

Design Goals

You need to define the design goals to choose a debossed or embossed packaging design.

Prefer Vector Art

It is important to start with the vector art file of the final design instead of a raster file. Vector art is composed of mathematical rules with the flexibility of size to ensure the quality of the transmission of smoothness into the embossed die.

Select Perfect Section

Embossing allows you to choose a small embellishment, pattern, image, logo, or text for embossing. It is true that debossing and embossing look fabulous as an accent. The recurring pattern through embossing on a small printed piece such as a business or invitation card offers a touch of sophistication.

Simple Artwork

Debossing and embossing provide literal dimensions to a 2D image. Embossing conveys elegance when it‘s performed on a simple artwork. However, artwork designed or shaded to appear in 3D may not look perfect when embossed.

Dedication Of Area For Design

When you are doing multi-level embossing, it is important to consider the deepest area for the largest part of the design. It is important to remember that paper can tear when you start embossing on a very small design section.

Heavier Paper Stock

It is a good approach to prefer a heavier paper stock and a detailed die for the effective embossing of different elements to showcase the detailed graphics and depth of printing quality.

Consider Print Piece

You need to prioritize the back of your print piece because embossing affects the design of this specific area. It has brought a phenomenal opportunity to add elegant visuals to your print piece.

Both debossing and embossing packaging designs elevate your brand, offering a memorable and unique look to your products. It is important to understand the differences, advantages, disadvantages, and uses of these packaging techniques to make a well-informed decision to differentiate your products.

Conclusion

Debossing and embossing are two unique and premium printing techniques for packaging. You can define debossed as a recessing approach for the texture and graphics of customized product packaging. However, embossing is familiar as a raising approach for texture and graphics. Therefore, you need to choose embossing or debossing based on your requirements.